| Usage/Application | Highway |

| Surface Finish | Powder Coated |

| Bottom Size | 130/135 A/F mm |

| Base Plate Size | 220X220X12 mm |

| Top Size | 70 A/F mm |

Specifications:

| Pole Type | Height (Meter) | Top Diameter (mm) | Bottom Dia. (mm) | Sheet Thickness (mm) | Base Plate mm (L x W x T) | Foundation Bolt (No. xDiaxmm) |

| KOP03 | 3 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 450 |

| KOP04 | 4 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 450 |

| KOP05 | 5 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 450 |

| KOP06 | 6 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 600 |

| KOP09 | 9 | 70 | 155 | 3 | 250 x 250 x 12 | 4 x 20 x 700 |

| KOP010 | 10 | 70 | 155 | 3 | 250 x 250 x 16 | 4 x 24 x 750 |

| KOP011 | 11 | 70 | 175 | 3 | 275 x 275 x 16 | 4 x 24 x 750 |

| KOP012 | 12 | 70 | 175 | 3 | 275 x 275 x 16 | 4 x 24 x 750 |

| KOP013 | 13 | 125 | 270 | 3 | 340 x 340 x 20 | 4 x 24 x 900 |

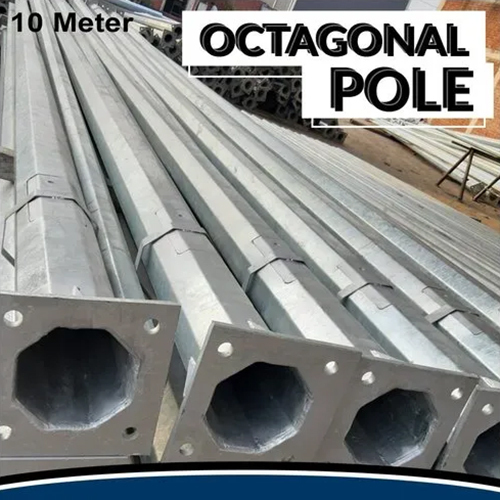

Superior Construction for Demanding NeedsCrafted from premium mild steel and shaped into an octagonal profile, these 10-meter poles exemplify durability and resilience in industrial use. The hot dip galvanization process ensures a corrosion-resistant surface, making them highly dependable for outdoor environments where longevity and strength are crucial.

Versatility Across Industrial ApplicationsThese octagonal poles find extensive usage in industrial sectors. Their design and surface protection make them preferred choices for street lighting, perimeter security, and infrastructural projects. The 10-meter height offers optimal illumination or support as required in expansive industrial zones.

FAQs of 10 Meter Octagonal Poles:

Q: How are the 10 Meter Octagonal Poles manufactured?

A: These poles are manufactured using high-quality mild steel, shaped into an octagonal profile. The poles undergo a hot dip galvanization process, ensuring comprehensive corrosion protection and extending service life, making them suitable for rigorous industrial environments.

Q: What are the main applications for these octagonal mild steel poles?

A: The 10 Meter Octagonal Poles are primarily used for industrial applications such as street lighting, outdoor area lighting, and providing structural support within factory premises, industrial parks, and large open storage yards.

Q: When should I choose an octagonal pole over a standard round pole?

A: Octagonal poles offer better wind resistance and stability compared to standard round poles. They are ideal for situations where additional structural integrity is required, such as in outdoor environments subject to strong winds or heavy loading.

Q: Where are these octagonal poles manufactured and supplied?

A: These poles are produced in India by specialized manufacturers and are supplied across the country to cater to diverse industrial and infrastructure projects.

Q: What is the surface finishing process used on these poles, and what are its benefits?

A: The poles undergo hot dip galvanization, which involves immersing the steel structure in molten zinc. This process creates a robust, corrosion-resistant coating, significantly enhancing the poles durability and reducing maintenance needs.

Q: How should these poles be installed for maximum stability?

A: Installation typically involves securely anchoring the pole base into a concrete foundation, ensuring that the octagonal design provides even load distribution and increased resistance to bending or tilting under stress.

Q: What advantages do the 10 Meter Octagonal Poles offer for industrial usage?

A: These poles provide excellent support and longevity due to their robust construction, corrosion resistance, and tall profile, which are essential features for large-scale industrial lighting and infrastructure projects.