| Usage/Application | Highway |

| Surface Finish | Powder Coated |

| Bottom Size | 130/135 A/F mm |

| Base Plate Size | 220X220X12 mm |

| Top Size | 70 A/F mm |

Specifications:

| Pole Type | Height (Meter) | Top Diameter (mm) | Bottom Dia. (mm) | Sheet Thickness (mm) | Base Plate mm (L x W x T) | Foundation Bolt (No. xDiaxmm) |

| KOP03 | 3 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 450 |

| KOP04 | 4 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 450 |

| KOP05 | 5 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 450 |

| KOP06 | 6 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 600 |

| KOP09 | 9 | 70 | 155 | 3 | 250 x 250 x 12 | 4 x 20 x 700 |

| KOP010 | 10 | 70 | 155 | 3 | 250 x 250 x 16 | 4 x 24 x 750 |

| KOP011 | 11 | 70 | 175 | 3 | 275 x 275 x 16 | 4 x 24 x 750 |

| KOP012 | 12 | 70 | 175 | 3 | 275 x 275 x 16 | 4 x 24 x 750 |

| KOP013 | 13 | 125 | 270 | 3 | 340 x 340 x 20 | 4 x 24 x 900 |

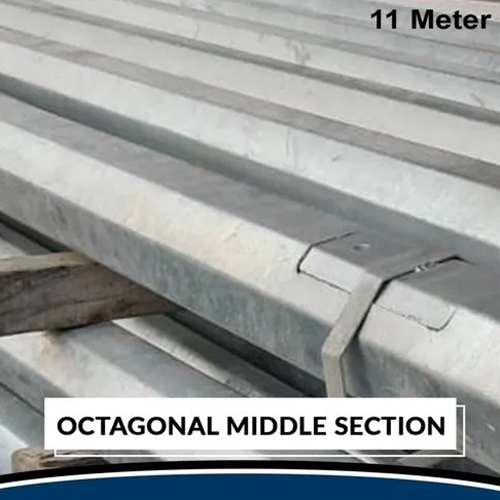

Durable and Reliable ConstructionProduced from premium mild steel, the 11 Meter Octagonal Pole features a robust design tailored for industrial settings. Its octagonal cross-section makes it exceptionally strong while optimizing material usage. The hot dip galvanized finish adds an extra layer of protection against rust, ensuring the poles longevity even in challenging outdoor environments.

Versatile Industrial ApplicationsThese octagonal poles serve a wide array of industrial needs, from mounting outdoor lights to supporting communication devices like CCTV cameras. Their 11-meter height is well-suited for illuminating wide areas such as factory premises, warehouses, or parking lots, enhancing security and visibility for various operations.

FAQs of 11 Meter Octagonal Poles:

Q: How is the 11 Meter Octagonal Pole most commonly used?

A: This octagonal pole is primarily utilized in industrial environments for mounting street lights, CCTV cameras, signage, and other equipment that requires robust elevation and support.

Q: What material is used to manufacture the 11 Meter Octagonal Pole?

A: The pole is made from mild steel, which provides excellent strength and resilience, making it suitable for demanding industrial applications.

Q: When is it advisable to use a hot dip galvanized pole?

A: Hot dip galvanized poles should be used in outdoor or industrial settings where exposure to moisture and harsh weather is expected, as the galvanization process prevents rust and extends the poles service life.

Q: Where can these poles be installed?

A: These octagonal poles are suitable for installation in industrial complexes, manufacturing plants, parking lots, warehouses, and other outdoor locations requiring reliable structural support.

Q: What process is followed to finish the poles surface?

A: The pole undergoes a hot dip galvanization process, where it is submerged in molten zinc to coat the surface, providing a corrosion-resistant finish and enhancing durability.

Q: What are the benefits of using an octagonal pole over a round one?

A: Octagonal poles offer greater stability and load-bearing capacity thanks to their geometric shape, ensuring safer installations and longer lifespan compared to conventional round poles.