| Usage/Application | Highway |

| Surface Finish | Powder Coated |

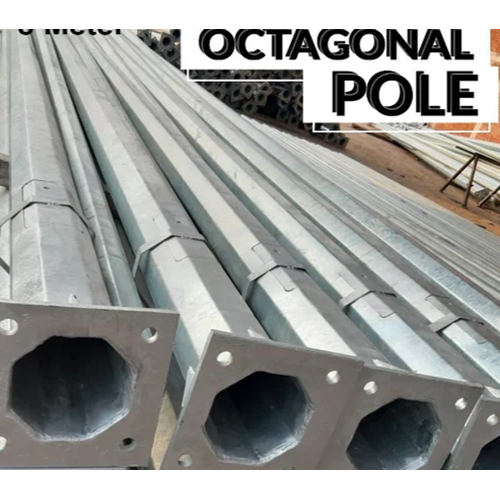

| Bottom Size | 130/135 A/F mm |

| Base Plate Size | 220X220X12 mm |

| Top Size | 70 A/F mm |

Specifications:

| Pole Type | Height (Meter) | Top Diameter (mm) | Bottom Dia. (mm) | Sheet Thickness (mm) | Base Plate mm (L x W x T) | Foundation Bolt (No. xDiaxmm) |

| KOP03 | 3 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 450 |

| KOP04 | 4 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 450 |

| KOP05 | 5 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 450 |

| KOP06 | 6 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 600 |

| KOP09 | 9 | 70 | 155 | 3 | 250 x 250 x 12 | 4 x 20 x 700 |

| KOP010 | 10 | 70 | 155 | 3 | 250 x 250 x 16 | 4 x 24 x 750 |

| KOP011 | 11 | 70 | 175 | 3 | 275 x 275 x 16 | 4 x 24 x 750 |

| KOP012 | 12 | 70 | 175 | 3 | 275 x 275 x 16 | 4 x 24 x 750 |

| KOP013 | 13 | 125 | 270 | 3 | 340 x 340 x 20 | 4 x 24 x 900 |

Reliable Industrial Structure SupportOur octagonal polygonal poles are specifically engineered for industrial use, aligning strength and versatility. Their polygonal shape ensures improved stability and load distribution, making them suitable for large-scale projects like factories, warehouses, or outdoor installations. Their mild steel composition and meticulous construction make them a dependable structural solution.

Advanced Galvanized Surface ProtectionThe hot dip galvanized finish provides outstanding resistance to moisture, rust, and harsh environmental conditions. This process coats each pole in a uniform layer of zinc, ensuring long-term performance even in severe industrial or outdoor applications. The silver color complements industrial aesthetics while safeguarding against corrosion.

FAQs of Octagonal Poles:

Q: How are these octagonal polygonal poles manufactured for industrial use?

A: These poles are manufactured in India using high-grade mild steel, shaped into a polygonal (octagonal) form, and then finished with a hot dip galvanization process. This ensures both structural strength and long-term durability in various industrial environments.

Q: What are the main applications of the octagonal polygonal poles?

A: These poles are primarily used in industrial settings, such as for factory lighting, power distribution, support structures, and outdoor installations where robust and reliable support is essential.

Q: When should I choose hot dip galvanized octagonal poles over other types?

A: You should opt for hot dip galvanized octagonal poles when your project requires enhanced corrosion resistance, exceptional structural integrity, and longevityespecially in demanding industrial or outdoor conditions.

Q: Where can these poles be installed for optimal performance?

A: These poles are best suited for industrial environments, including warehouses, production plants, outdoor operational areas, and any location that requires reliable, corrosion-resistant support structures.

Q: What is the process involved in hot dip galvanizing the poles?

A: Hot dip galvanizing involves immersing the mild steel poles in molten zinc, creating a robust layer that adheres to the surface. This protects the poles from rust, corrosion, and environmental degradation.

Q: How do octagonal (polygonal) poles benefit industrial applications compared to other shapes?

A: The octagonal shape distributes stress more evenly and offers better wind resistance, making these poles more stable and durable in high-demand applications compared to traditional round poles.