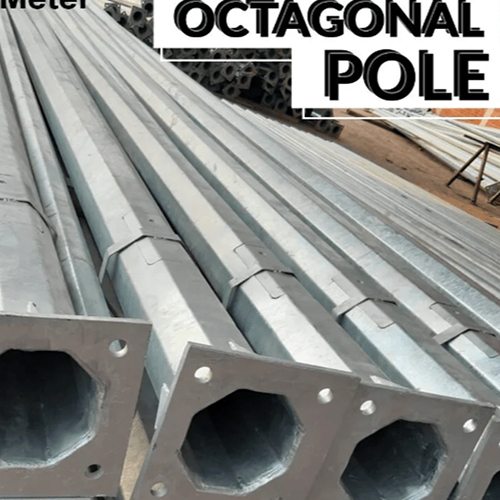

Specifications:

| Pole Type | Height (Meter) | Top Diameter (mm) | Bottom Dia. (mm) | Sheet Thickness (mm) | Base Plate mm (L x W x T) | Foundation Bolt (No. xDiaxmm) |

| KOP03 | 3 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 450 |

| KOP04 | 4 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 450 |

| KOP05 | 5 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 450 |

| KOP06 | 6 | 70 | 130 | 3 | 200 x 200 x 12 | 4 x 16 x 600 |

| KOP09 | 9 | 70 | 155 | 3 | 250 x 250 x 12 | 4 x 20 x 700 |

| KOP010 | 10 | 70 | 155 | 3 | 250 x 250 x 16 | 4 x 24 x 750 |

| KOP011 | 11 | 70 | 175 | 3 | 275 x 275 x 16 | 4 x 24 x 750 |

| KOP012 | 12 | 70 | 175 | 3 | 275 x 275 x 16 | 4 x 24 x 750 |

| KOP013 | 13 | 125 | 270 | 3 | 340 x 340 x 20 | 4 x 24 x 900 |

Exceptional Durability for Industrial UseEngineered from high-quality mild steel and finished with hot dip galvanization, these octagonal poles are built to withstand diverse weather conditions and resist corrosion. This ensures long service life and minimal maintenance, making them a trusted choice for a variety of industrial and outdoor environments.

A Versatile Lighting SolutionDesigned for versatility, these poles can be deployed in a wide array of settings such as industrial estates, roadways, municipal parks, and commercial complexes. Their robust construction and modern design allow for seamless integration into different landscapes while providing dependable light support.

FAQs of Street Light Octagonal Pole:

Q: How is the Street Light Octagonal Pole installed?

A: The installation process typically involves anchoring the poles base plate to a prepared foundation using bolts, followed by securing the lighting fixture onto the top. It is recommended that installation is carried out by professionals to ensure structural integrity and proper alignment.

Q: What are the main benefits of using an octagonal pole over a round or square counterpart?

A: Octagonal poles provide increased structural strength, superior wind resistance, and a modern aesthetic. The shape evenly distributes stress, reducing the risk of bending or deformation, which is crucial in high-traffic or exposed industrial environments.

Q: When should hot dip galvanized poles be selected for outdoor lighting projects?

A: Hot dip galvanized poles should be chosen whenever durability and corrosion resistance are priorities, especially in harsh or humid outdoor settings. The zinc coating effectively protects the mild steel core from environmental damage, extending the poles usable life.

Q: Where are these octagonal poles commonly used in industrial applications?

A: These poles are widely utilized in factory complexes, industrial parks, main roadways, parking areas, and other commercial properties requiring robust and reliable outdoor lighting infrastructure.

Q: What is the manufacturing process for mild steel, hot dip galvanized poles?

A: These poles are first fabricated from mild steel sheets, shaped into the octagonal profile, and welded. After fabrication, they undergo a hot dip galvanizing process, where the pole is submerged in molten zinc to form a strong, protective coating.

Q: How does the hot dip galvanized finish benefit pole maintenance and longevity?

A: The hot dip galvanized coating acts as a powerful barrier against rust and corrosion, minimizing maintenance needs and sharply increasing the poles operational lifespan, even in challenging outdoor environments.